Find Corrugated Tile Roll Forming Machine, Cold Roll Forming Machine, Tile Roll Forming Machine on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

| Payment Type: | L/C,T/T |

|---|---|

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 60 Days |

Model No.: ZGM-Tile, ZGM-Tile

II. Tile Roll Forming Machine paramters A. Composition of machine Roll forming main machine………………………….…1 unit 10 Tons hydraulic de-coiler with coil car………….1 set Punching system……………………………………1 units Control panel…………………………………………..1 unit Hydraulic station……………………………………1 unit Spare tools……………………………………………one box B. Details of each composition De-coiler 1. Single unrolling machine, one side can put material. 2. Adopt automatic hydraulic system. 3. Coil weight (Max):10000kg. 4. Inter diameter: 470mm-520mm. 5. Maximal out diameter:1800mm. 6. Oil cylinder dia:120mm working pressure: 20mpa (=20Tons). 7. Coil width (Max.):1000mm. 8. Working speed: 0-25m/min. 9. Power: 5.5KW. 10. Hydraulic power: 3kw. 11. De-coiler should be with Loop control and hold down. 12. Coil car: 10Tons. 13. The motor power of coil car: 3Kw. 14. Pressure: 12Mpa. Roll forming main machine 1. Coil width: 1000mm effective width:930+3-3 mm (design base on 3mm). 2. Working speed: 0-20m/min (not contain cutting and punching). 3. Roll station: 17stations material of roller: Gcr15 bearing material; polished and coated with chrome HRC58-62°. 4. Material of main shaft: 45 forge steel(Same as SAE1045) diameter roller: 150mm. 5. Main power: 45kw, forming thickness: 2.5mm—3.5mm, Transmission: by chain. 6. Roll former has leveling bolts in the base. Cutting 1. Machine adopt hydraulic cutting. 2. Cutting after forming: Cut the sheet after roll forming to required length. 3. Cutting motion: The main machine automatically stops and the cutting will take place. After the cutting, the main machine will automatically start. 4. Material of blade: CR12with heat treatment . 5. Length measuring: Automatic length measuring . 6. Tolerance of length: 4700mm+/- 2mm. Control panel (1)Voltage, Frequency, Phase: 380 V, 50 Hz, 3Phase (2)Automatic length measurement. (3)Automatic quantity measurement. (4)Computer used to control length & quantity. Machine will automatically cut to length and stop when required quantity is achieved . (5)Length inaccuracy can be amended easily. (6).Control panel: Button-type switch and touch screen. (7)Unit of length: millimeter (switched on the control panel). (8) Laguage: English, Spanish and Chinese. III. Tile Roof Roll Forming Machine forming&working process A. Working process

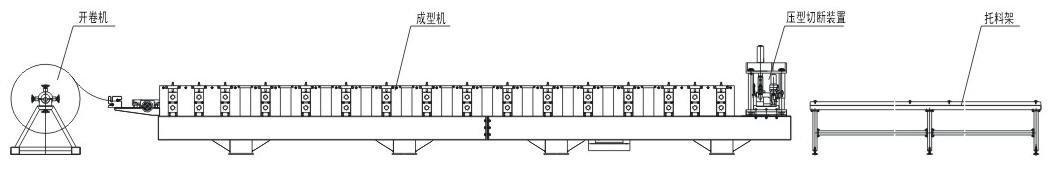

II. Tile Roll Forming Machine paramters A. Composition of machine Roll forming main machine………………………….…1 unit 10 Tons hydraulic de-coiler with coil car………….1 set Punching system……………………………………1 units Control panel…………………………………………..1 unit Hydraulic station……………………………………1 unit Spare tools……………………………………………one box B. Details of each composition De-coiler 1. Single unrolling machine, one side can put material. 2. Adopt automatic hydraulic system. 3. Coil weight (Max):10000kg. 4. Inter diameter: 470mm-520mm. 5. Maximal out diameter:1800mm. 6. Oil cylinder dia:120mm working pressure: 20mpa (=20Tons). 7. Coil width (Max.):1000mm. 8. Working speed: 0-25m/min. 9. Power: 5.5KW. 10. Hydraulic power: 3kw. 11. De-coiler should be with Loop control and hold down. 12. Coil car: 10Tons. 13. The motor power of coil car: 3Kw. 14. Pressure: 12Mpa. Roll forming main machine 1. Coil width: 1000mm effective width:930+3-3 mm (design base on 3mm). 2. Working speed: 0-20m/min (not contain cutting and punching). 3. Roll station: 17stations material of roller: Gcr15 bearing material; polished and coated with chrome HRC58-62°. 4. Material of main shaft: 45 forge steel(Same as SAE1045) diameter roller: 150mm. 5. Main power: 45kw, forming thickness: 2.5mm—3.5mm, Transmission: by chain. 6. Roll former has leveling bolts in the base. Cutting 1. Machine adopt hydraulic cutting. 2. Cutting after forming: Cut the sheet after roll forming to required length. 3. Cutting motion: The main machine automatically stops and the cutting will take place. After the cutting, the main machine will automatically start. 4. Material of blade: CR12with heat treatment . 5. Length measuring: Automatic length measuring . 6. Tolerance of length: 4700mm+/- 2mm. Control panel (1)Voltage, Frequency, Phase: 380 V, 50 Hz, 3Phase (2)Automatic length measurement. (3)Automatic quantity measurement. (4)Computer used to control length & quantity. Machine will automatically cut to length and stop when required quantity is achieved . (5)Length inaccuracy can be amended easily. (6).Control panel: Button-type switch and touch screen. (7)Unit of length: millimeter (switched on the control panel). (8) Laguage: English, Spanish and Chinese. III. Tile Roof Roll Forming Machine forming&working process A. Working process  Roller hydraulic decoiler → Roll forming → Cutting → Table out IV. Tile roof roll forming machine roof sheet&profile drawing

Roller hydraulic decoiler → Roll forming → Cutting → Table out IV. Tile roof roll forming machine roof sheet&profile drawing  Contact us if you need more details on Light Industrial Glazed Tile Roof Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any Other aspects about Roof Tile Sheet Rolling Forming Machine、Glazed Tile Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Light Industrial Glazed Tile Roof Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any Other aspects about Roof Tile Sheet Rolling Forming Machine、Glazed Tile Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Roof&wall roll forming machine > Tile roof roll forming machine