Product Description

Model NO.: 910 Condition: New Usage: Roof, Wall, Floor Feeding Width: 1000mm Main Frame: 300 H Steel Welded Voltage: 380V 3phase 50Hz Thickness: 0.3-0.8mm Trademark: XH Origin: Botou City, China Certification: SGS, CE, ISO Customized: Customized Transmission Method: Machinery Effective Width: 910mm Diameter: 70mm Main Power: 3kw Warranty: 12 Months Specification: SGS, CE, ISO HS Code: 8455221000 Crimped Steel Wall Panel

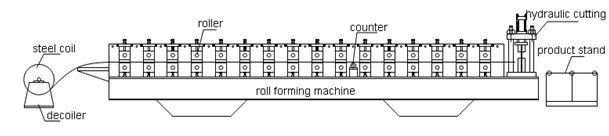

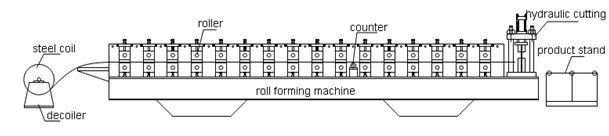

roll forming machine(XH910)

2.Producing Process Show: |

3.Equipment Technical Pamameter: |

Main Forming Machine Technical Pamameter:

machine size | 5800mm*1400mm*1300mm |

Feeding width | 1000mm/1250mm |

Equipment weight | 3.5T |

Material of shaft | 45#steel adjustable treatment |

Out diameter of shaft | φ70mm |

Material of roller | Cr12, quenched treatment HRC58-60°C |

Number of forming rollers | 12 standard rollers |

Main frame | 300 H steel |

Thickness of medium plate | 14mm |

Transportation system | Chain transportation |

Thickness of chain | 0.6 inch |

Main motor power | 3 KW |

Bearing | 6213 |

Forming speed | 8-12m/min |

Rolling thickness | 0.3-0.8mm |

Ps:Parameters above is the standard configuration.Parameters can be designed as per your special requests. Hydraulic Shearing System:

Material of blade | Cr12,heat treatment 60-62°C |

Shearing system | It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank, the pumps drive the cutter machine to begin the cutting job. The system includes a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes. And two sets of electromagnetism valves. Power of the oil pump: 4kw Hydraulic oil :40# |

Electrical System:

Screen display | 5.7 inches touch screen |

Main computer control cabinet | It adopts industrial computer to control. The target piece's length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use. Processing precision : within 1.00mm It contains liquid crystal screen, programmer, transformer for the electronic machines and kits of every part. Transducer brand is TaiWan"taida" The seller should provide Chinese and English language screen. |

1) Pre-sale service: Freely provide project designing, process designing, choosing suitable equipment for you. 2) Medium-sales service: Accompany you to complete the acceptance of the equipment,draft the construction scheme and detailed process, and complete process of export 3) After-sales service: We sent engineer to the scene to guide installation, debugging and training operators.

FAQ

1) Q: Are you manufacturer or trading company?

A: We are manufacturer and trading company .

2) Q: Do you provide installing and training overseas?

A: Overseas machine install and worker training services are optional.

3) Q: How is your after sales support?

A: We provide technical support on line as well as overseas services by skillful technicians.

4) Q: How does your factory do regarding quality control?

A: There is no tolerance regarding quality control. Quality control complies with ISO9001. Every machine has to past testing running before it's packed for shipment.

5) How can I trust you that machines pasted testing running before shipping?

A: 1) We record the testing video for your reference. Or,

2) We welcome you visit us and test machine by yourself in our factory.

6) Q: Do you sell only standard machines?

A: No. Most machines are made to order.

7) What should I provide if I`d love to customized my machine?

A: To customize machine, we`d love to know:

1. Profile drawing

2. Raw material: the width(1250mm?), thickness(0.3-0.7mm?), and yield strength of steel coil.

3. Voltage: designed per your requirement

4. Configuration requirement: Hydraulic or manual decoiler/ stacker

Have no idea about them?

We will be glad to recommend machines ----Just let us know your country!

Contact us if you need more details on

Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any

Other aspects about Roll Forming、

Cold Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Roof Sheet Forming Machine