Product Description

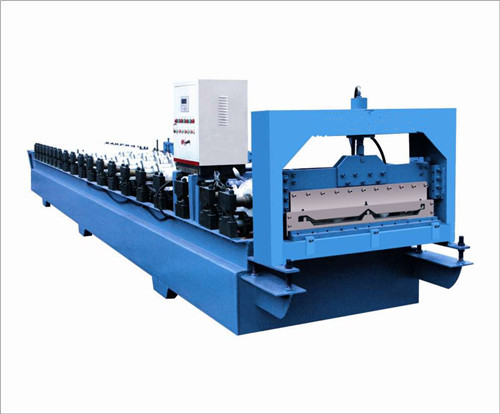

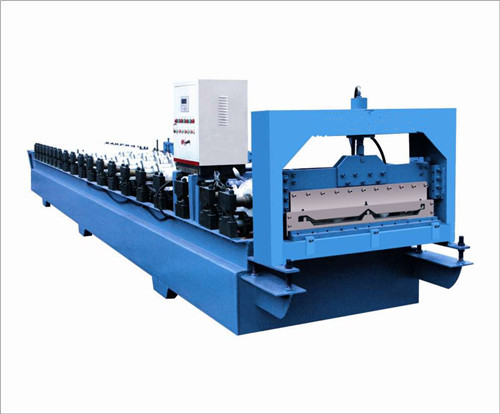

Model NO.: 760 Forging Forming Method: Mold Forging Feature: Automation Warranty: 12 Months Advantage: Work Flexible Feeding Width: 1000mm Main Frame: 300 H Steel Welded Main Power: 5.5kw Control Systerm: PLC Control Trademark: XH Specification: SGS, CE, ISO HS Code: 8455221000 Type: Rolling Machine Power Source: Hydraulic Pressure Certification: SGS, ISO9001, CE Customized: Customized Condition: New Effective Width: 760mm Thickness: 0.3-0.8mm Chain: 1.5 Inch Type1: Roll Former Machine Transport Package: Naked and Fasten in The Container Origin: Botou City, China Botou Xinghe

Roll Forming Machinery Co.,LTD

If you are free to know more about our machine and our company, please visit: www.xhrollformingmachine.com

If you are interested in our products and we hope you can come to our factory to check machine by yourself to know our machine quality level. When you come, pls inform me and we will arrange to pick you up from airport

Production flow chart:

Un coiler---feeding---Roll forming---Cut to length---Final product

Techinical Parameter

No. |

|

|

1 |

Main motor power |

5.5kw |

2 |

Hydraulic station power |

4kw |

3 |

Sprocket |

P-25.4 |

4 |

forming station |

21 |

5 |

Material of roll |

45#steel hard chrome plating |

6 |

Length of production line |

10m |

7 |

Installation dimension about(L*W*H) |

9.6*1.8*1.4m |

8 |

Total weight |

5T |

9 |

Diameter of principal axis |

70mm |

10 |

Hydraulic oil pump |

CB-E310 |

11 |

Material of blade |

Cr12 |

12 |

Thickness |

0.3-0.8mm |

13 |

Equipment parts |

roll forming system, forming press system, hydraulic system, computer control system, counter, cutting, cutting system, material feeding support. |

14 |

Process flow |

decoilling -loading-molding- tile forming-cutting-off- discharing |

Our Services

1.)we can send our engineer to your site and do the training for your men. you just only bear the cost for our engineer's air ticket,visa,accormadation,food and transpotaion in your country

2.)You can send your men to our factory. we will teach them how to operate the machine without training charges

3. )Actually theres another cheap and easy way to choose. Every machine leave our factory with one book of operation manual. You can read through the manaul first ,and get familiar with the machine. Then we can get a video call,and teach you on-line how to operate the machine.

4.)Apart from above training course,we also provide 1 year warranty for all the easily broken part of the machine for free and whole-life technical service support !

FAQ

1) Q: Are you manufacturer or trading company?

A: We are manufacturer and trading company .

2) Q: Do you provide installing and training overseas?

A: Overseas machine install and worker training services are optional.

3) Q: How is your after sales support?

A: We provide technical support on line as well as overseas services by skillful technicians.

4) Q: How does your factory do regarding quality control?

A: There is no tolerance regarding quality control. Quality control complies with ISO9001. Every machine has to past testing running before it's packed for shipment.

5) How can I trust you that machines pasted testing running before shipping?

A: 1) We record the testing video for your reference. Or,

2) We welcome you visit us and test machine by yourself in our factory.

6) Q: Do you sell only standard machines?

A: No. Most machines are made to order.

7) What should I provide if I`d love to customized my machine?

A: To customize machine, we`d love to know:

1. Profile drawing

2. Raw material: the width(1250mm?), thickness(0.3-0.7mm?), and yield strength of steel coil.

3. Voltage: designed per your requirement

4. Configuration requirement: Hydraulic or manual decoiler/ stacker

Have no idea about them?

We will be glad to recommend machines ----Just let us know your country!

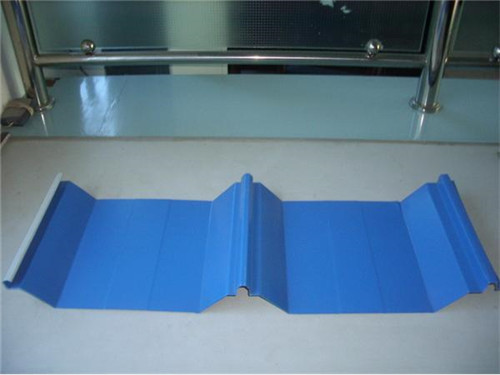

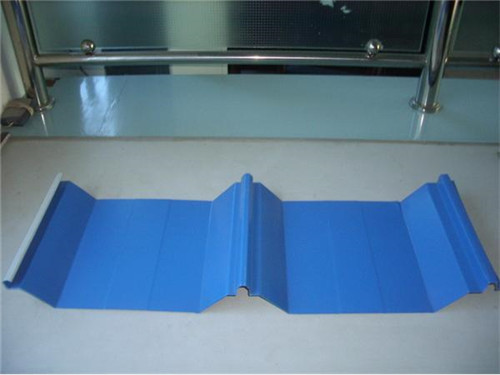

Contact us if you need more details on

Roofing Sheet Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any

Other aspects about Joint-Hidden Forming Machine、Joint-Hidden Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Jonint-hidden Machine